PRODUCT

Robotic Arm

YASKAWA

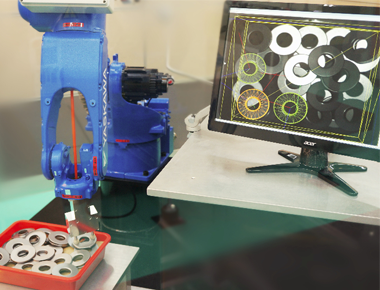

Equipment Introduction :

Carrying 2D and 3D visual system, high-accuracy inspection and substantial improvement in identification. Respond to wide range of multi-layer work objects, reducing the use of clamp fixture and providing more possibility of automation.

Robot Introduction:MOTOMAN-MH12

Upgrading mobility speed, strengthening loading capacity, arm streamline, improving mobility flexibility, reducing interference with peripheral fixture, ARM hollow-design, and convenient pipeline concealing.

Equipment Introduction:

Frequently used in the application of food, drug, cosmetics, and small object grabbing. Amazing speed and agility that meet high-speed moving demand on conveyor belt. Carrying visual system and conveyor concurrent performance to accurately and quickly grab the object, shortening the preparation time plus MOTOPICK software that reduces the majority of TEACHING process.

Robot Introduction:MOTOMAN-MPP3H MOTOMAN-MPP3S

Featuring the fastest moving capacity, implementation of high productivity, maximum activity range, and minimum setup space with more advancement in hygiene and safety management.

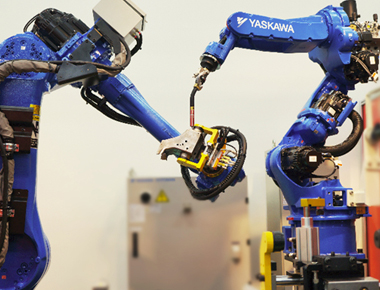

Equipment Introduction:

The application of robot welding is quite extensive and can substantially improve efficiency and capacity as the personnel is only responsible for feed loading and unloading while the robot can complete the welding work to substantially improve the productivity performance. The high reproduction of robot, voltage, current and speed as well as stable distance can stabilize the weld quality, thereby reducing the defect rate substantially. The cooperation of two robots can reduce the opportunity of fixture while expanding the scope of welding mobility and reducing blind spots. The mutual coordination and motion in synch can complete more high-accuracy welding work.

Robot Introduction:MOTOMAN-VA1400

The 7-axes robot offers more flexibility in activity angle and provides excellent welding performance. The upward improvement of motion features can accelerate the production speed, reduce the area of welding equipment, apply to the introduction of high-density space welding system equipment, pipeline concealing design, and reduce interference with external risk.

Robot Introduction:MOTOMAN-MH50

Multi-purpose extensive robot substantially upgrades the speed and mobility scope compared with older model. Additionally the inertia and torque tolerance of the hand is the maximum compared with similar models. When applied in humid environment, choose the hand with IP 67 and main unit of IP65 OPTION (standard model is hand IP67 and main unit IP54).

Equipment Introduction:

Flexible change: program-controlled to deliver different products to different pallets. High safety: Using machines to replace manpower and reduce occupational accident. Improving productivity: reducing manpower for moving with different robotic tools to meet the different moving demand. Various cartons and bag-based packaging materials for free use without restriction.

Robot introduction:MOTOMAN-MPL80

One robot suitable for stacking and moving with the maximum transport processing capacity. High speed processing and small setup space requirement to maximize the work area.

Equipment Introduction:

High speed and excellent accuracy of robot can incorporate with various sensors to place objects concisely on processing sites.

● The system replaces manpower processing, substantially increases productivity and reduces processing costs.

● Comprehensive system planning substantially improves economic benefits.

Loaded with SERVO FLOAT to satisfy customers with relevant demand.

SERVO DOOR can be incorporated with robot speed for motion and improvement of production efficiency.

Robot introduction:MOTOMAN-MH24

ARM Hollowing makes it convenient for pipeline concealing design and can be incorporated with new DX200 controller box for addition of multiple new functions.

OMRON

Equipment introduction:

Most suitable for food, drug and medical devices industry.

Series robot includes Hornet series and Quattro series.

Quattro series refer to 4-axes series robot that can realize high-speed and high-accuracy with high loading.

Robot introduction:Hornet 565 / Quattro 650/800

The amplifier and controller built into the robot saves cabling and reducing storage space.

Equipment Introduction:

4-axes level multi-joint robot suitable for assembly, transport, package, working machinery processing, and the high speed and high accuracy of screw tightening.

Robot introduction:Cobra 350 / eCobra 600/800 / eCobra 800 Inverted

Providing two installation methods – platform and hanging

Equipment introduction:

6-axes vertical multi-joint robot suitable for assembly, material moving, packaging and stacking.

Robot introduction:Viper 650/850

Processing/assembly/transport vertical multi-joint robot.

Kaiplus Technology CO., LTD.

-

Address : No.316, Ding’an St.,Annan Dist.,Tainan City 709,Taiwan(R.O.C)

Address : No.316, Ding’an St.,Annan Dist.,Tainan City 709,Taiwan(R.O.C) -

TEL : 886-6-255-2606

TEL : 886-6-255-2606 -

FAX : 886-6-255-2607

FAX : 886-6-255-2607 -

Email:sales@kaiplus.com.tw

Email:sales@kaiplus.com.tw